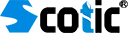

Drill bits for Stone/Metal/Wood

- +86 (0)21 5865 1575

- +86 (0)21 5865 1579

- sutek@sutek-industry.com

Our Features

Drill bits for Stone/Metal/Wood

Hammer Drill Bits; Concrete Core Drill Bits; Masonry Drill Bits; Glass & Hard Tile Drill Bits SDS-plus Hammer Drill Bits with Professional ...

Read MoreManufacture & Packaging & Delivery

As a export-oriented drill bit enterprise, we are always firmly to control every packing details for good delivery ...

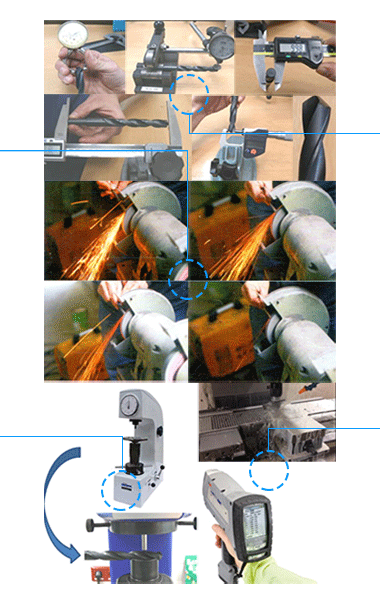

Read MoreQuality inspection & Technical indicator

Quality inspection is a must before delivery based on Sutek Quality Control Documents or Customer Request Documents...

Read MoreLatest Drill bits

our product catalogue pdf document

Download our product catalogue for more information. go to downloads page now.

We Provide Multiple Standards & Specifications

International Standardization Organization

Multiple standards and specifications see our products.

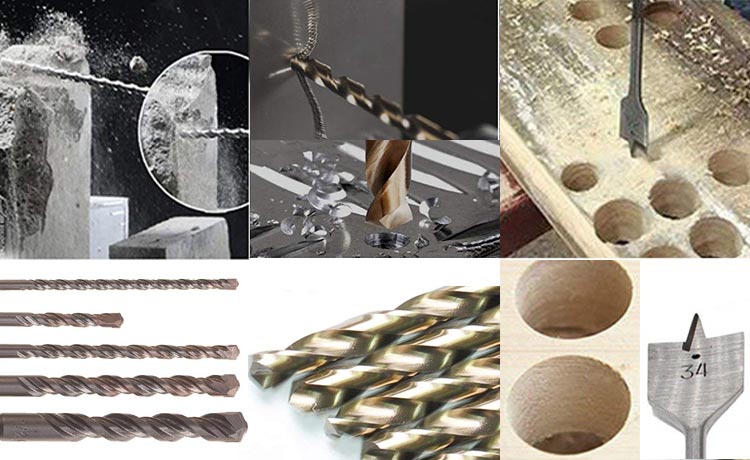

Number of flutes cutters

2/3/4/5/6/7/8 Flute cutter ballnose, 2/3/4/5/6/7/8 Flute square end.

Responsive Design

30/45/55/118/135° Point Geometry.

Labore et dolore magna aliqua

Our design is with responsive in mind. Our themes are compatible with various desktop, tablet, and mobile devices.

Amber Surfaces

Perfect plating Amber surface treatment for enhancing hardness and wear resistance, the hardness increased by about 10 times at most.

TiALN Surfaces

Perfect plating TiALN surface treatment for enhancing hardness and wear resistance, the hardness increased by about 15 times at most.

Quality Inspection