- +86 (0)21 5865 1575

- +86 (0)21 5865 1579

- sutek@sutek-industry.com

High Quality

The best Raw Materials of Made in China. The best machine we updated. Under the best quality system of Sutek Industries.

Shipping

International transport agency business of export goods in whole container and assembled container from Shanghai Port.

Best Price

The best solution for standard products and tailor-made. Give you a sample quotation immediately.

Tailor Made

Tailor made tools in special field. Custom specialist on aluminum. Give you a sample designing.

Free Packing

Free design packing for our customer based on their own market. Give you a choice from our manner of packing.

Drill bits applications scotic

Drill Bits For Stone

Products Range: Hammer Drill Bits; Concrete Core Drill Bits; Masonry Drill Bits; Glass & Hard Tile Drill Bits SDS-plus Hammer Drill Bits with Professional qualities under DIN/ANSI standard SDS-plus or max are available. SDS-plus Hammer Drill Bit are made for professional quality only to drill various concrete, bricks, masonry materials, etc. Super quality carbide is taken for most durable drilling performance. Auto-copper soldering is under German tech. guaranteeing the best advantages in drilling. Automatic-copper-soldering guarantees best welding strength and copper wrapping carbide for prolonged drilling life. Over 1200 centidegree soldering temperature guarantee the drill bit fitting different working environments

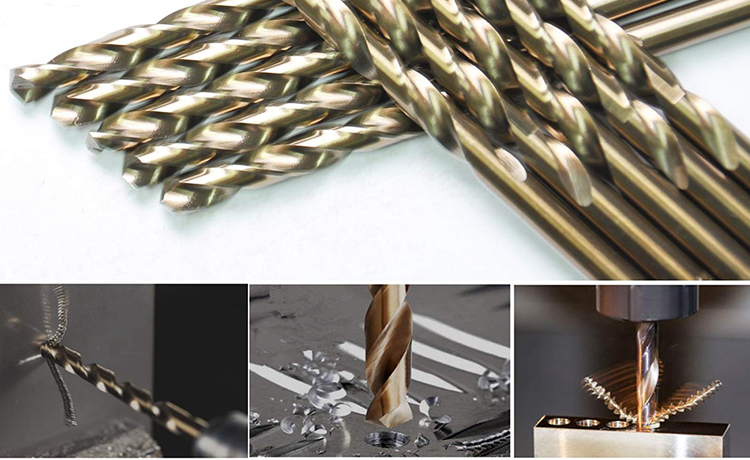

Drill Bits For Metal

Manufactured from M42/M35/M2/W3 steel, with molybdenum and cobalt added to creates a hardened alloy, measuring Rockwell hardness up to 67 with 5% Cobalt, for much faster cutting and extra longer life span, with up to twelve times when compared with an average HSS drill bit. No center punch is needed—the 135° Quick-Cut points are self-centering and penetrate quickly with less pressure. Will not "walk" or "wander" Extremely heat resistant; must be used and operated at 1500 RPM or greater for maximum efficiency. Straight shank allows for firmly holding and accurate centering, fit for standard drill chucks and regular round collet chucks Manufactured with all kinds of drill bit for metal, such as HSS Twist Drill, HSS Center Drill Bit, HSS Step Drill Bits, Reduced Shank Drill Bit, Taper Shank Drill Bits, and etc. Made into HSS Twist Drill Bits; HSS Step Drill Bit; Taper Shank Drill Bits; Reduced Shank Drill Bits; Bi-metal Hole Saw

Drill BitS For Wood

Manufacture from Flat wood drill bit to Brad Point Wood Drill Bits; Wood Auger Bits; Extension for Spade Drills; Wood Forstener Bit; Wood Router Bits; HSS Saw Drills; Plug Cutter; Hollow Mortising Chisel Bit; Self feed wood working bit. Spade bits use double-cutting spurs that scribe the outside of the hole, reducing breakout Flat drill bit design features a large shank for added durability Blue-Groove point and cutting edge for faster chip removal - 4x faster than standard spade bits

Exportation Standards scotic

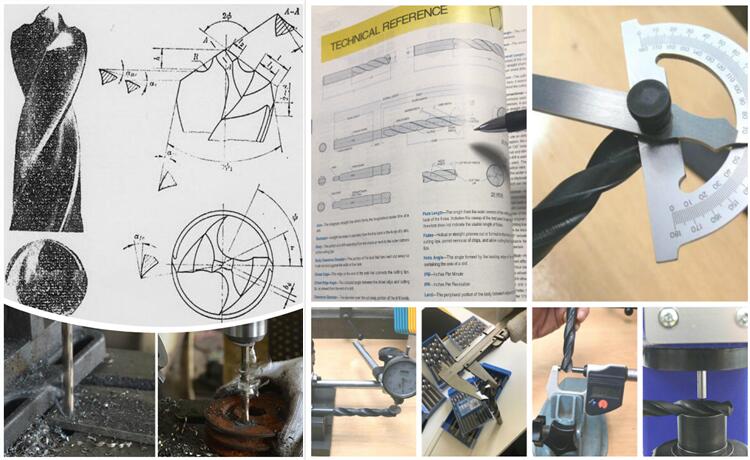

Our Drill Bits Material

It is often used in power-saw blades and drill bits. It is superior to the older high-carbon steel tools used extensively through the 1940s in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high carbon steel, hence the name high-speed steel. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above Rockwell hardness 60) and abrasion resistance (generally linked to tungsten and vanadium content often used in HSS) compared with common carbon and tool steels.

Manufacture & Packaging & Delivery

As a export-oriented drill bit enterprise, we are always firmly to control every packing details for good delivery.

Quality Inspection

Quality inspection is a must before delivery based on Sutek Quality Control Documents or Customer Request Documents.